Best Crate Engine For The Money (Mega Guide): 2022 Edition

Update – January 2022 [We’re afraid that 3 of the 4 products reviewed here are not available on Amazon for now. Incidentally, the only available product on our list has proven to be the best of the lot since long back when the article was originally written in 2018.]

If you’re looking for a quick verdict, here you go:

[After 8 hours of researching on 4 of the best crate engines available on the market, we found out that Genuine GM (10067353) 350ci / 5.7L Gen 0 Engine is the one that truly deserves your hard earned money.

The LS3 E-ROD Crate Engine – Chevrolet Performance E-ROD LS3 6.2L Automatic Crate Engine is our latest recommendation for the year 2022. It is made for the environmentally conscious users who still want only the best for their vehicle. The after-sales service for LS platform crate engines is commendable.]

Keep scrolling down to dive into a detailed review of all three engines, and also a brief background on what crate engines are, their features and uses, and what are the factors you must consider before making a purchase.

Crate Engine to the Rescue

We love our cars. The look of a shiny and raring to go vehicle does make us feel alive. But it is important to take care of its inside machinery just as well as we take care of the outside. A car engine is the powerhouse of a vehicle. And that is why it is important to fix or replace it when the need arises. We don’t want the whole car to suffer by picking a new glossy paint coat over the pending engine replacement.

Now, the engine replacements are not the most affordable upgrades. But only if you have not heard about the crate engine. They are the affordable and quality solution for all your engine related troubles. Lately, everyone is taking note of them and reviving the life of their vehicle from inside out.

Crate engines are the modern-day answer to the requirement of a brand-new but easy on budget engine replacements. The aftermarket companies are exploring this domain and offering the customers various customized options in the form of automobile components, parts, and even ready-to-install race car engines.

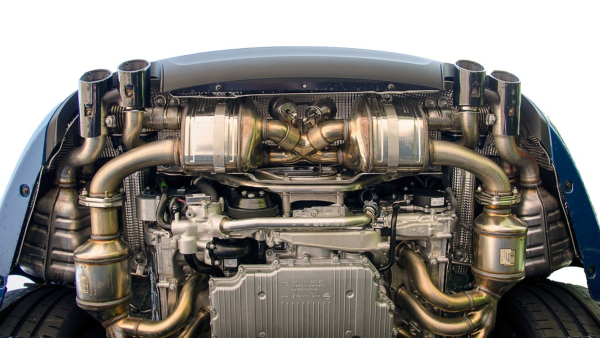

Get blown away by the sound of a 1000hp modern crate engine, and then we shall proceed further!

The car is not much without a powerful engine. And now we can make sure that the ones we are driving are always in the best shape thanks to the crate engine. There are a number of applications of the crate engine. And with the passage of time, more and more car engineers are making it possible for every car owner around the globe to have a mechanical beast for an engine.

Crate Engine: Features and Uses

A crate engine can be defined as a brand new car engine that has been shipped in a complete form along with the cylinder heads. We can just take it out of the ‘crate’ and install it in our car directly or get a professional to do so, depending on our mechanical prowess.

Manufactured by the experienced engine builders, they are designed and crafted to perfection. They come with a warranty card after all the final models have gone through enough quality tests to reassure us about it.

The reasonable price tag makes it possible for us to pick the crate engines over the much expensive modifications that are bound to jeopardize our total budget. The durability and mileage are other factors where a crate engine gives you a good bargain over the much expensive versions. We found it to be a small investment with massive returns.

Main Features

A lot of beneficial features make the crate engines the hot favorite of all the seasoned car enthusiasts. All these engines are brand new and fully assembled by the best people in the business. Their exemplary overall performance is the reason that their popularity has skyrocketed in the recent years.

The warranty for most of them is minimum two years that is a testament to the confidence that the manufacturers have on their product. The engines can be customized to our preferences too. Most of these engines offer various options when it comes to deciding the engine finish including the show-quality polished finish and the traditional satin finish.

Primary Uses

Crate engines can be useful in a variety of applications. This is why more and more people are resorting to incorporating them in their hot wheels. Few prime uses are:

- A number of Motorsports Competition events such as the Asphalt, Dirt Track, Drag Racing have the participants swapping their engine for the powerful race track suitable crate engines.

- Standard automobile engine replacement can also be done using the crate engine.

- Heavy-duty marine engines are also created in the format of a crate engine.

- Customized high-power crate engines are also available for the Transformers fans out there.

Factors To Consider Before Buying

The crate engines might be the next best thing created in the automobile industry. But still, we cannot go with anything that anyone presents to us. We have to take care of the few important things before finalizing our decision. The following list will surely be helpful for the same.

Brand New Over Rebuilt

There is not a vast difference between the pricing of a rebuilt model and a brand new model. But with the rebuilt model, we are actually getting an engine that has been exhausted and then rebuilt. Chances are, we will end up with a substandard quality product that will give out soon.

That is not the case with a brand new crate engine. We get an engine with all the brand new parts and that is further backed by the warranty card for at least a couple of years to come. There are just so many benefits of picking a brand new engine over a rebuilt one and the almost similar price tag is surely one of them.

Pick Horsepower over Torque

The thing with horsepower is that we can always increase it later on by making slight modifications later on. But the torque stays the same for the engine from start to finish. So it is better to go with a model that has the right torque to handle everything that we plan on putting our engine through.

The torque specifications will help us in working out the acceleration of our cars. A high-performance crate engine helps us to accelerate our car as fast as we want without any delay. This way we will be leading the journey at the desirable speed every single moment of it.

Steer Clear of Fakes

A great deal of effort goes into making the fake products look just like the one most of us wish to purchase. That is why we have to be extra careful with the crate engines. The duplicate crates are a parallel industry that runs on the gullibility of the unassuming people.

That is why it is better to explore the product carefully before making the final purchase. This way we will be able to notice even the minutest of the details that might help us in steering clear of the fake rate engines. As a result, all our time and money investment will only be going to the genuine crate engine that we were intending to buy originally.

Best Crate Engine For The Money

Today, we can find a lot of suitable options when we are looking for a crate engine for our pair of wheels. But few of them are worth every single penny. Below are top three of those options :

1. Genuine GM (10067353) 350ci / 5.7L Gen 0 Engine

Main Features

As one of the best entry-level engine for optimum performance, this crate engine can be used in a variety of vehicles. This includes the cars, trucks and street rods. It has all the brand new parts which make sure that we never have to compromise on the quality.

The many components that come along with this model include painted valve covers, oil pans, and timing covers. This way you don’t have to compromise on the quality just because of the dipstick orientation. This is the perfect engine for you if you are trying to get back some life in your old car without breaking the bank.

Pros

- It has been drilled to accommodate both left and right-hand dipstick.

- Cast iron has been used to manufacture the strong engine heads.

- These cylinder heads come with the 1.94-inch intake valves

- At 1.50-inch exhaust valves, the cylinder heads are guaranteed to offer you that edge in performance.

- This crate engine further boasts of the 76 cubic capacity combustion chambers accompanied by the 7-bolt style exhaust flanges.

Cons

- Currently, these products are not available for international shipping process.

- Some users report being underwhelmed by its performance on the road after installation in their respective vehicles.

2. PitsterPro PP-160-HO-Honda High Output 160cc crate engine (HONDA PORT)

Main Features

Currently, this crate engine has been touted to be the hottest brand of the moment. Its portability and easy accessibility have helped in making it a household name across the globe. The flexibility is one of the key factors that make it a celebrated crate engine all over the world. Weighing at just 45 pounds, it is a lightweight yet powerful addition to your current set of wheels.

Pros

- Along with this model, you are provided the oil cooler, lines, and mounting bracket.

- The smooth operation is ensured with the help of the outer rotor ignition.

- The basic structure of the outer setting comes along with the wiring harness, ignition coil, and CDI box.

- The transmission mode follows the 4-up manual (N-1-2-3-4).

- Just keep the clutch pulled in and it will start in any gear.

Cons

- The motor could have been jetted in a better manner with a bit more attention to detail.

- The international shipping is yet not available for this model across major international cities.

3. HPRE 427700 – Chevy 427 Racing Crate Engine 700Hp

Main Features

This crate engine has been designed especially to give that unbeatable performance to the race car engines. All the components have been designed in a way that the friction and the extreme pressure during the deciding moments does not affect the performance even a bit.

Pros

- The model impresses with a splendid 700+ hp specifications.

- The fuel is used judiciously and effectively with the help of custom forged pistons(13.5-1 Compression).

- More life is added to the engine with the help of polished aluminum valve covers.

- With the custom grind steel billet roller cam, you achieve the next level of performance.

- The consistency and quality of the operation are attained with the help of 4340 6.000″ H-beam connecting rods.

Cons

- It is not suitable for the race car engines that require the engine to be gentle on the screeching tires.

- Its durability has been a big concern with all the latest reviews pointing out the obvious pitfalls.

4. LS3 E-ROD Crate Engine – Chevrolet Performance E-ROD LS3 6.2L Automatic Crate Engine

Main Features

The engine comes with CARB approval for its green initiative towards the emission structure. The LS platform of the Chevrolet Performance E-ROD LS offers an impressive 424 foot-pounds of torque and 430 horsepower.

Pros

- It has sufficient basic installation setup including the headers, air cleaners and wiring.

- This engine has a comparatively lighter body due to the implementation of composite intake manifold and aluminium block heads.

- This reduces overall weight on the front axle and enables better weight distribution.

- For automatic transmissions, you get a 40 tooth reluctor wheel with this engine.

- You get 24 months or 50,000-mile warranty with the purchase.

Cons

- You don’t get the charging, cooling, induction system or the transmission with the order.

- It costs ten thousand dollars at present. An amateur can build a more powerful model in lower price.

This wraps up our list of the best crate engines available commercially for all you automobile DIY wizards out there.

Types of Crate Engines

Crate engines come in four main types. You have to pick your battles and make peace with the one that has more pros for your current purpose than its cons.

1. Rebuilt Engines

Rebuilt engines are exactly as they sound, they undergo their very own building process from the start. The given engine is first disassembled and analyzed properly. The worn out and damaged parts are then replaced with brand new ones to give its performance a better shot.

All the parts are properly cleaned too when disassembled and then reassembled by using only components that adhere to the OEM standards. It includes mainly the lubricants, seals, and gaskets. Overall, the O rings, timing belt or chain, valve springs, oil pump, bearings, gaskets, and the seals are the most commonly replaced components.

The major parts of the engine are replaced only if it is absolutely required for proper functioning. The pistons, crankshafts, and camshafts are the ones that are usually replaced in this case. There are just two main scenarios where rebuilding the engine is not possible.

Rebuild Till You Can

Firstly, when an internal component punches a hole in the engine block and its exterior gets windowed/cracked. Engine rebuilding can’t be done in this case. Secondly, the broken connecting rod or crankshaft can do internal damage to the engine block thus making it impossible to rebuild it in any manner. However, in almost every other case, engine rebuilding is very much possible.

The most important reason to rebuild the engine is to retain the connectivity that the ECU of the vehicle had with the original engine. You will need to reprogram or replace the ECU even if you replace the old one with a brand new engine. But by rebuilding it, you will save a good deal and help reduce the toxic scrap in the environment too.

2. Remanufactured Engines

The engines that are sent all the way back to the original manufacturer and re-engineered/ reconditioned to match the original specifications are known as the remanufactured engines. They use a combination of completely new, reused and repaired components to design the final product.

This process is carried out by properly certified technicians backed by the original manufacturer for the refurbishing process. The engine is repaired and the faulty components are replaced to restore the premium performance. The final result is an engine that strictly adheres to the standards and specifications set for the original engine of this brand.

In certain cases, a rickety car may still possess a pretty useful engine. It can be remanufactured easily where the parts will be either replaced or altered mechanically to restore its original invincible form. This way we can recycle in the automobile world and do our bit for the environment.

A Step Ahead of the Rebuilt Engines

The engine where the buyer is expected to accept it in ‘as-is’ form is a big red flag. It might not be remanufactured at all and the customers have the right to ask for a suitable warranty with every remanufactured engine. In other cases, people often use the terms ‘rebuilt’ and ‘remanufactured’ interchangeably.

And you will be on the losing end if you are on the buyer’s side of this transaction. The remanufactured engines go through an intensive calibration and quality testing process. The rebuilt engine doesn’t compare in terms of the quality and assurance that the remanufactured engines render to the vehicle.

3. New Engines

Depending upon from where you are buying the new engine, it can turn out to be a stellar deal. It can prove to be a hassle-free and reliable purchase as compared to all the other counterparts. If your favorite ride is giving you trouble for past few years then it might be a good time to give this engine replacement thing a try. It is always going to be a lot less expensive and sensible than going for a brand new car!

A new engine can breathe life even in a second hand run down the car if it has still some life left within it. You get a brand new start engine-wise with the engine replacement. And that means you don’t have to worry much about the stress you might be putting on your car as you cruise from one crossroad to another, not caring even a bit about the bumpy road ahead.

You Pay Premium Price for Premium Performance

You can pick the exact configurations that you want with a brand new engine. The amazing warranty further ensures your vehicle’s performance for the next couple of years and you can invest the money you saved by not going for a brand new car into something immediate and more mindful.

The few downsides that are associated with this range of engines include a higher insurance and tax rate. The depreciation cost is also quite high as compared to the other three kinds. But, aside from these numbered cons, the pros are practically infinite. If you have the time and money to go for a brand new engine without overplaying your hand then you should surely go for it.

4. Used Engines

A used engine is more of a gamble. You might get a winner for dimes or you might get stuck with a goner. You should go for a used engine only when you can’t afford any of the other kind of engines. It definitely is the most affordable of the three kinds of engines but also comes with the least reliability.

The process of engine replacement is quite expensive in terms of both time and money. You might get a good deal if you pick the right kind from the right place but still, you have to incur the labor hours. So, you don’t want to do that all over again if your gamble with the used engine does not yield. You have no way of knowing how much more it can serve and how it was being used by its previous owner.

Better than Remanufactured and Rebuilt Engines? May Be!

But, if you do hit the jackpot with this purchase, you will enjoy a flat depreciation rate along with lower insurance as well as tax rates. A used engine is also a ‘complete engine’. Other than the brand new engines, the other two categories involve a lot of mix and match. You somehow become its first test subject by using it outside the controlled test environment and actually dealing with its problems on the go.

The used engine has each and every component intact as it had since the time it was manufactured. After being scrapped from its original vehicle for whatever reason, now it is a complete engine ready to work just like it used to, in the next vehicle.

These were the main four categories of crate engines that can benefit you in your time of need. So choose wisely and drive carefree.

Crate Engine: Building vs Buying

You might not be the one who answers ‘neon blue’ when asked about the basic configuration of your current engine. Still, you are a long way from being a person who just happens to build create engines as per will. Building your own engine requires both skill and foresight. The end result should meet your requirements and can endure the tough conditions day after day without breaking down abruptly.

Begin The Analysis

To build your very own engine from scratch you must absolutely have an easily accessible machine shop, a wide range of specialty tools and a good understanding of how and which parts to connect together in an engine. This is the minimum basic requirement for being able to build your very own engine from scratch.

If you are familiar with terms like rod bolt stretch gauge and piston ring filer then you don’t need to worry and can just get started on the engine building process. Else, if you are good at putting a working engine in the desired vehicle then you can still use this skill of yours to save a considerable number of expensive labor hours.

And for the engine in question, you can simply hire a reliable engine builder and get the job done with a good bargain. A customized assembled crate engine will take care of all your requirements without you having to sell an arm and leg for it.

Are You Skilled And Prudent Enough

People vary and so does their skill set and requirements. You may or may not be better off building your own engine from scratch. Or, you might be one of those who choose to save their time and money by always going for a reliable and affordable steal.

The one step that is common for both these situations is the requirement to know the brand better. Whether you are assembling it together or getting it made crate style, you can always use a bit of research about the brand and more about the engine that you are planning to either build or buy.

It is only after you know the basics about the engine that you can create or buy the one that aligns perfectly with the requirements of your vehicle and your preferences. The experience level of the engine builder will make you more certain about your decision or help you make a better choice.

The Guarantee of a Warranty

Aside from the clever wordplay, this also serves as a key question that helps you make up your mind with regards to the nature of your engine replacement. You don’t get a warranty on a customized engine that you get built from your local machine shop or put together yourself.

With a crate engine, you will usually get a decent warranty. The unlimited miles warranty, 50 thousand miles warranty and 2-3 years of warranty are few of the very common warranty offers on the latest crate engines. You get a certain assurance of quality and accountability when you go for a branded crate engine.

But, there might be few minor expenses that you will have to pay for in case of occasional repairs and regular maintenance. It is not completely a one-time investment but the occasional expenditures are way less and more predictable than the ones which you will be facing with the engine that you choose to build or get built yourself.

Start With a Solid Engine Block And a Gameplan

Each engine is a complete functioning entity in itself. Observe its basic composition and notice how its components interact with each other. Only after this step can you actually start mapping out concrete details for the engine you have been contemplating.

Are you planning to go for the hypereutectic pistons or the forged ones? What about the H-bean and steel rods? All these decisions need to be made well in advance so that you can actually get a good value out of your engine. In the case of both custom – made engines and the affordable crate engine models, the seasoned factory blocks are used.

You don’t actually start with a fresh engine block. However, you can get a four-bolt main if you are really particular about it. You will just need to contact the right supplier for it if it is key to your building plans. The aftermarket blocks give you plenty of choices and you can actually get a good deal in this case with just a bit of research.

Pick The Right Cylinder Heads

Do you need the cylinder heads just as powerful as the ones used in the racing cars? No, problem. You can now get them with the same ease as ordering a pizza online. But, always consider the bottom line in the process.

What kind of performance and utility are you looking from these cylinder heads? Do they fall within your budget limit? Don’t buy yourself yet another white elephant that drains you financially for years to come. The main two options in case of the cylinder heads are the aluminum heads and the iron heads.

With aluminum heads, you get better heat dissipation and hence an edge in terms of the compression ratio. The iron cylinder heads keep the heat within the chamber to generate greater power. You can score the iron/cast iron heads at a more affordable price range as compared to the aluminum ones. But, each one is best in its own way depending upon the budget and requirements.

Induction System Selection Criteria

You need a suitable induction system to pump air inside the engine. Else, the entire fuel will come right out of the exhaust pipes. Sufficient amount of oxygen from the air will burn the fuel efficiently to keep your car running as you like.

The aspirated induction is the process where you simply rely on the air as it is around you to facilitate the fuel combustion. The forced induction system will use an additional gas compressor. This will to change the temperature, pressure and the density of the air.

This will enable better fuel combustion in a consistent manner. Now, you can control the variable of the fuel combustion better and make the changes to improve it for maximizing the performance. Then comes the carburetor which determines the speed of the engine by controlling a number of factors. It combines the air and fuel together to form a highly combustible mixture and controls their respective ratios in the said mixture.

Induction System Intake Options – Which Is Better For You?

When one can afford it, they first go for carburetor and performance intake. The two options are a single plane and dual plane intake. The common assumption states that dual plane is for street use and racing cars run on the single plane intakes.

As the name suggests, the dual- plane intake has two separate plenums feeding a set of 4 cylinders each. On the other hand, all the eight cylinders are fed by the same plenum in case of the single-plane intakes. The RPM range of the camshaft and the valvetrain need to match with the intake range to function in sync.

This average range will become the RPM range at which the engine will be running. The RPM range of the single plane intake is 1,500 to 1,700 rpm and that for the dual plane intake is 3000 and above. Always go with the dual plane intake with the street cars to make your journey comfortable and hassle-free.

Crate Engines – Install and Drive

If you are the nut-and-bolt-guy/girl who makes powerful engines in their spare time, a crate engine can still fit in your equation. It can be even more useful for the ones who don’t mind paying the price upfront. This enables them to drive away to the destination of their choice without any delay. The three main kinds of crate engine you have today are short block, long block and the complete engine.

You get the scope of tinkering with it yourself or customizing the remainder of it according to your requirements. The long block and short block ones have enough room to accommodate your choices. The tin work (valve covers, timing chain cover, and oil pan), gaskets, oil pump, cylinder heads and intake and carburetor can easily be chosen for. Subsequently, you can get it installed in the short block engine.

Customize or Buy the Finished Product At One Go

The long block crate engine comprises of everything that the short block engine has. It includes the timing chain and gears, a crankshaft, camshaft, pistons and connecting rods. The additional components present in the long block crate engines are intake and cylinder heads.

This is usually preferred during the engine replacement process. Just transfer all the working pieces from your big block anchor onto the long block crate engine and you are almost ready to drive. Other than the crate engine, you have two main options. You can build it yourself or getting it built according to you by someone reliable and experienced.

The forums and the theoretical knowledge alone won’t help you in solving the practical challenges of engine building. So, consult with the relevant machinist prior to the commencement. And, keep in mind to add a few extra bucks to the final estimate. This is because passion projects always end up costing just a bit more.

Crate Engines – Know Better to Buy Better

Staying updated on the current trends of the crate engine prepares you for the future purpose easily. Take a look at the following important guidelines and words of wisdom to make a smarter purchase next time.

Engine Block is the Foundation

It all starts with the engine block for all kinds of the engine. Some prefer to invest smarter now than to replace later. While others opt for an affordable purchase keeping in mind a future replacement. Depending upon the available resources and your current requirements, you should settle for the corresponding nature of the engine block.

The aftermarket companies are filling up this requirement void in a speedy manner. Today, you have no shortage of engine blocks belonging to all budget ranges and special requirements. You can either spend 1800 dollars on a solid engine block now and drive for years on end without ever having to stop for repairs.

Or, you can get a decent block for well under 200 dollars. Enjoy the prime of its service for the current year and then switch to a brand new engine block after its worn out. This way you will be giving your car a quality upgrade every other year well within your budget.

Enquire about the Specifics

In this case, the quality is in the details! It is only after you have gone through the troubles of the engine replacement that you become wiser for a smoother operation the next time around. But, if you are reading this article, you can very well be pro-active about it. With just a bit of attention and care, you can take care of every big and small detail for minimal discomfort.

Dig around and get to know the company from which you are planning to get the crate engine. Get its price across different shopping portals. Know how much will it be ensured for. How will the delivery be done? Will the delivery truck have a hydraulic lift or forklift to remove it from the truck? All these details must be taken care of to protect your purchase at all times.

What about the crate engine tuning? What exhaust, carburetor and induction system should you go with? The synthetic oils are gaining momentum but should the blends and natural oil be totally discarded? A bit of time and effort invested early on will help you get a good start on the whole installation process and usage.

Quality Comes With a Price

With a brand new engine replacement, you and your car, both might feel invincible for a while. But, ultimately you will be getting only as much as you have invested in. This applies for both the cost and the know-how about its working and maintenance. So, don’t flinch at the idea of investing in a bit costly but useful machine parts. They will pay off in the long run and you will pat your past self on the back for making this insightful decision.

Even if two engine has almost the same parts, their construction can still be vastly different. Get a reliable builder and don’t try to skim in the preparation process. The right builder may cost a bit more but power through so that you don’t have to gamble with the possibility of pushing your car at midnight in the middle of nowhere till you reach somewhere everytime you put the keys in.

Purpose over Options

Going for a roaring racing engine makes no sense if you are just going to use your car for office and groceries. You don’t need the supersonic hotwheels for these everyday mundane tasks. Instead of that, go for a feature that you are actually going to make good use of and which fits well in your current routine.

How much power consumption are you actually aiming from this new engine and will you be actually making use of it? Are you going to add nitrous or superchargers for improving the speed among other factors? Is your vehicle going to be parked for long duration and might suffer from overheating. All these questions will help you make a useful purchase with no useless expensive additions whatsoever.

Oversee And Get To Know The Parts And Process a Bit

Don’t annoy everyone around you by constantly bombarding them with questions. But, separating yourself from the whole engine building process can also create problems for you later on. Get to know your engine a bit. Chat up the mechanics working on it so that you stop creating your own names for the parts whose name and purpose you know nothing about.

This way, you will know that just ordering the most expensive parts do not end all your worries. You can very well be adding more in terms of upkeep. They might also not sync in well with the other part if you don’t organize the engine carefully. The mid-range for horsepower is a safe bet.

Also, keep the builder in the loop for the first few months after installing the new engine. You can get certain recommendations regarding breaking the engine and priming the oil system. Also, ask for a buildsheet that contains the number of all parts, tightening specifications and tolerances. This will add value to the car in the form of detailed documentation when you choose to sell it later. Also, it will come in handy during replacements, invoking warranties and upgrades.

These are few of the many points that can help you get more worth out of your crate engine. Keep them in mind when going for the next upgrade.

How To Install a Crate Engine?

Crate engine installation can be quite simple if the steps involved are followed in the correct manner and sequence. Also known as the engine-in-a-box, the crate engine installation differs from the conventional engine replacement process in more ways than one. Read on to know the five main steps involved in crate engine installation.

1. Make Your Choice

Get to know the latest in the world of crate engine better before finalizing your purchase. The size, power, price and several other variables need to be defined by you first. This way, you will not come even close to the buyer’s remorse after making the transaction.

Crate engines are a hit because of the ease, affordability and accountability that they come with. You get to upgrade your car without spending a ton of money, time or effort and the final result is mostly outstanding since people are still not able to grasp the applicability of these amazing aftermarket offerings.

If you have taken up a passion project or are just putting together a custom car kit, the crate engines can shave off a good chunk of expenses from your overall budget. Building an engine from scratch requires a lot of patience and commitment aside from the obvious access to the best in machining equipment. You have to be ready mentally, physically and financially to pick something else over the easily accessible crate engines.

Important Selection Concerns

The performance claims of quality crate engines can now be backed with the Dyno test. It involves the engine being run against controlled resistance. And the true value of torque, horsepower and the engine’s power can be generated. The dynamometer will thus generate the true readings of all these vectors. But, this process might add a few extra dollars to the final price too. If you can afford it then go for it.

The dyno test relieves you from the duty of having to break-in your engine. It also adds proper verification to the actual output of the engine so that you don’t get a disappointing surprise later on. The crate engines can be short- block, long-block or complete with respect to configuration. You need to prep for the installation process accordingly and factor in the price of additional components too.

2. Pull Out The Old Engine

The old engine needs to be handled and taken out carefully. Start with unbolting the hinge attentively and calmly remove it. Drain the radiator and remove it when completely empty. Disconnect the ground cable of the battery. Do the same for the air and fuel supplies.

Now unbolt the hoses for power steering and the air conditioner but don’t disconnect them. Disconnect the exhaust manifold safely and remove all possible wiring from the motor region. Jack up the car only after unbolting transmission connections.

Make sure that you are taking a few pictures and making brief notes about this process. It would help you to keep track of all the big and small tasks that need to be taken care of without getting overwhelmed. Exhaust pipe needs to be removed followed by the transmission bracing process for unfastening it with the help of a jack stand.

Take Care of Details

Start unbolting the motor mount. Use the hoist to remove the old engine by lowering the jack stand. Now, keep the engine away from the working area so that it does not get in the way and stays intact. If you don’t have the complete crate engine then you will be making good use of the various working parts of this discarded engine block.

But always stick to the instructions of the manufacturer when it comes to installing new parts in your engine. You don’t want to tinker with a working recipe. If you think you have a better option in mind then just cross check with the manufacturer once. This way you will be saving your brand new crate engine from going up in flames even before your car enjoys this upgrade.

3. Prepare For The Replacement

Unpack the crate engine and observe it keenly. This way you can be able to scan it for any and all damages that might have been caused during the shipping process. You can ask for a replacement or refund if it is covered in the manufacturer’s policy.

After this, check the oil valve for metal shavings. Fill up oil in the crankcase and the filter. Use a drill motor to rotate the oil pump shaft. This will lubricate the inside of the engine. Inspect the new engine properly to see if it will fit all the older brackets, manifolds and hoses.

The spark plug timing at the distributor cap must be checked beforehand. The flow onto the rocker arms can be verified properly by pulling on the valve covers. Match the carburetor jets with the appropriate displacement by resizing them. You must purchase or fabricate new components if the old ones are affecting the crate engine adversely.

4. Drop The Engine

Use a hoist to lower the engine into the required place and keep it leveled at all times during this process. Now, fasten the engine suitably between the mounting brackets. After this, simply reconnect all the wires, hoses and pipes and see if the connection is properly established between the components and the new engine.

In the meantime, maintain a proper distance between the exhaust headers and the heat sensitive components. Reinstall the hood and the radiator too. Finally, the engine replacement process is complete. But you still need to break-in the engine among other minor steps.

Ensure that a solid contact is maintained at all time between the ground wire and the frame for the proper functioning of the engine. Add a suitable coolant mix to the radiator. The fiberglass-bodied cars require good grounding for optimum performance.

5. Initiate The Break-In Process

You need to break-in the engine carefully to set up a strong foundation for the engine’s life for the years to come. Start with keeping the gearshift in either park or neutral position even before you start the engine. Chock the wheels and set the car in emergency brake if you are on the ground. Now turn the ignition key to fire up the engine.

If the engine does not show the required activity just don’t keep on cranking the ignition key. This is a clear indication that you need to adjust the fuel delivery system. After fixing this issue, kick off the engine and run it at 2,000 rpm right away. This helps in dissipating the oil on the camshaft.

Initiate proper break-in by varying the revolutions strictly between the range of 1,800 to 2,500 rpm for the next 20 minutes. It will be better to have someone along for this whole process. They can assist you in monitoring the oil pressure and water temperature gauges without missing out on any important details.

Pay Attention To The Response

For the first few hours, you need to pay attention to how the car and the newly installed engine are interacting. The electrical systems should be charging the battery efficiently. Prevent the coolant leaks by checking their flow after removing the radiator caps.

After 30-minutes or so, check the carburetor setting and the ignition timing to correct any faults there. Pulleys must be in proper alignment to assist in the smooth operation of the entire vehicle after the replacement. Drive at about 60 mph for the next five to six medium throttle accelerations. Subsequently, let go of the throttle and come back down to 20 mph.

Make sure you keep the next 500 miles under the 50 mph margin. Avoid putting excessive stress on the engine, extended periods of hard use and other rash driving situations. Change the filter and oil within the first 100 miles.

By following all these cautions, you have now equipped your engine efficiently for every kind of challenge ahead. Now your car is ready to once again go for those long drives to somewhere far in both rain and sunshine!

Conclusion

Our cars become our partner in the journey of life very soon. That is why it is always better to keep them updated and in proper shape. You never know which sharp turn around the corner might topple the performance levels of your cherished vehicle. Crate engines are the best new solution for all your engine replacement related troubles.

Have you used a crate engine until now? Tell us how much better or worse they have made your life since their installation. Let us know what you want to read next about. We are eagerly waiting for your feedback and review in the comments section below.